China 6 dhidibkii 1800mm cudud waxay gaadhaysaa birta toosan ee MIG alxanka Robotic Arm

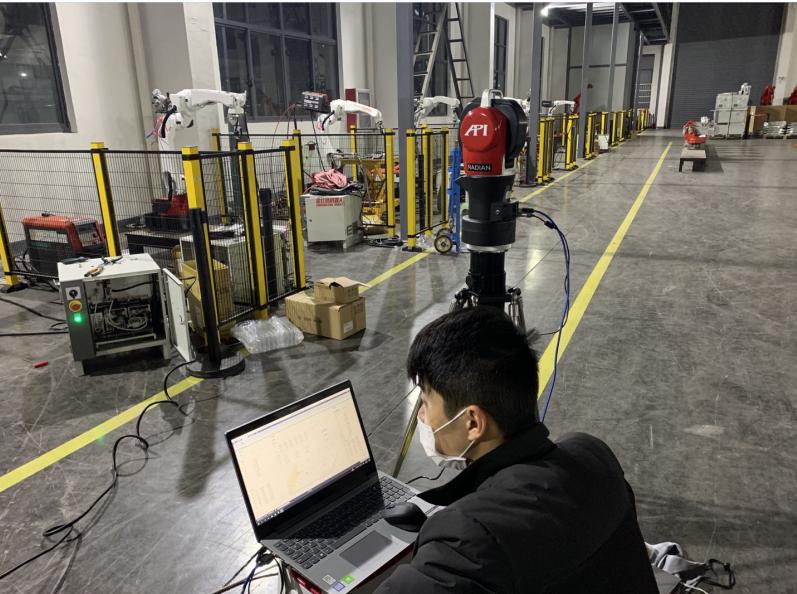

Saxnaanta dib u soo celinta Tijaabada CALIBRATION LASER

JHY waxay isticmaashaa habka cabirida laysarka si ay u tijaabiso saxnaanta meelaynta soo noqnoqda ee robotka.Tijaabooyin badan ka dib, saxnaanta meelaynta soo noqnoqda ee robotkeena ayaa aad uga sareysa ± 0.08mm.

U ISTICMAALO SAMAHA UGU SAREEYA agabka muhiimka ah

Qalabka asaasiga ah ee Robot-ka sida servo motor, RV reducer, harmonic reducer, servo drive iyo wixii la mid ah dhammaan waxay isticmaalaan noocyada ugu sarreeya Shiinaha, kuwaas oo lagu tijaabiyay isticmaalka muddada-dheer si loo hubiyo inay ku habboon yihiin robotkeena.

Dayactirka FUDUD

Dayactirka waa mid fudud, Marka loo eego hagaha dayactirka ee ay bixiyaan macaamiisha laftooda ayaa si fudud u shaqeyn kara.

DAMMAANAD IIBKA KA DIB

Macaamiil kastaa wuxuu leeyahay koox adeeg iibka kadib u gaar ah.Haddii aad u baahan tahay wax caawimaad iib ah ka dib, Pls weydii wakhti kasta.Injineeradayada xirfadlayaasha ah ayaa xallin doona waqtiga ugu gaaban.Ujeedadu waa dhamaanteed waa bilaash.

| Qiyaasaha alxanka tixraaca birta khafiifka ah iyo birta daawaha hoose | |||||||||

| nooca | saxan | Dhexroorka siliga | farqiga xididka | hadda alxanka | danab alxanka | xawaaraha alxanka | Xiriirka fogaanta tip-workpiece | socodka gaaska | xagal alxanka |

| alxanka dabada u qaabaysan | 1.0 | 0.8 | 2.5~3 | 70-80 | 17-18 | 8 ilaa 10 | 10 | 10 ilaa 15 | 45° |

| 1.2 | 1.0 | 3 ilaa 3.5 | 85-90 | 18 ilaa 19 | 8 ilaa 10 | 10 | 10 ilaa 15 | 45° | |

| 1.6 | 1.0,1.2 | 3 ilaa 3.5 | 100 ilaa 110 | 18-19.5 | 8 ilaa 10 | 10 | 10 ilaa 15 | 45° | |

| 2.0 | 1.0,1.2 | 3 ilaa 3.5 | 115 ilaa 125 | 19.5 ilaa 20 | 8 ilaa 10 | 10 | 10 ilaa 15 | 45° | |

| 2.3 | 1.0,1.2 | 3 ilaa 3.5 | 130 ilaa 140 | 19.5 ilaa 21 | 8 ilaa 10 | 10 | 10 ilaa 15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5~4 | 150 ilaa 170 | 21 ilaa 22 | 7.5 ilaa 8 | 15 | 15 ilaa 20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5~5 | 180 ilaa 220 | 21 ilaa 23 | 6.5-7.5 | 15 | 15 ilaa 20 | 45° | |

| 1.2 | 5-5.5 | 200-250 | 24 ilaa 26 | 6.5~8 | 10 ilaa 15 | 10 ilaa 20 | 45° | ||

| 6 | 1.2 | 5-5.5 | 230-260 | 25 ilaa 27 | 6.5-7.5 | 20 | 15 ilaa 20 | 45° | |

| 6 | 220-250 | 25 ilaa 27 | 5.5-7.5 | 13 ilaa 18 | 10 ilaa 20 | 45° | |||

| 4 4.5 | 270-300 | 28-31 | 10-11.5 | 13 ilaa 18 | 10 ilaa 20 | 45° | |||

| 8,9 | 1.2,1.6 | 6 ~7 | 270 ilaa 380 | 29-35 | 6.5-7.5 | 25 | 20 ilaa 25 | 50° | |

| 8 | 1.2 | 5~6 | 270-300 | 28-31 | 9.10 | 13 ilaa 18 | 10 ilaa 20 | 45° | |

| 1.2 | 7~8 | 260 ilaa 300 | 26 ilaa 32 | 4 – 5.5 | 15 ilaa 20 | 10 ilaa 20 | 50° | ||

| 1.6 | 6.5~7 | 300-330 | 30-34 | 5-5.5 | 15 ilaa 20 | 10 ilaa 20 | 50° | ||

| 12 | 1.2,1.6 | 7~8 | 270 ilaa 380 | 27-35 | 4.5 ilaa 6.5 | 20 ilaa 25 | 20 ilaa 25 | 50° | |

| 1.2 | 7~8 | 260 ilaa 300 | 26 ilaa 32 | 4 – 5.5 | 15 ilaa 20 | 10 ilaa 20 | 50° | ||

| 1.6 | 6.5~7 | 300-330 | 30-34 | 5~6 | 15 ilaa 20 | 10 ilaa 20 | 50° | ||

Fiiro gaar ah:

1. Alxanka MIG waxa uu isticmaalaa gaas aan shaqaynayn, oo inta badan loo isticmaalo alxanka aluminiumka iyo alwaaxdiisa, copper iyo alloys, titanium iyo alloyskeeda, iyo sidoo kale birta aan fiicnayn iyo birta u adkaysata kulaylka.alxanka MAG iyo CO2 gaaska ka ilaaliya alxanka waxaa inta badan loo isticmaalaa alxanka birta carbon iyo aluminium hoose bir xoog sare.

2. Nuxurka kor ku xusan waa tixraac kaliya, waxaana ugu wanaagsan in la helo cabbirada habka alxanka ee ugu fiican iyada oo loo marayo xaqiijin tijaabo ah.Dhexroorka siliga kore waxay ku saleysan yihiin moodooyinka dhabta ah.